Ask your retailer

You found your retailer is part of our HD network? Perfect!

Your usual retailer is not in our network yet? Talk to them about HD quality!

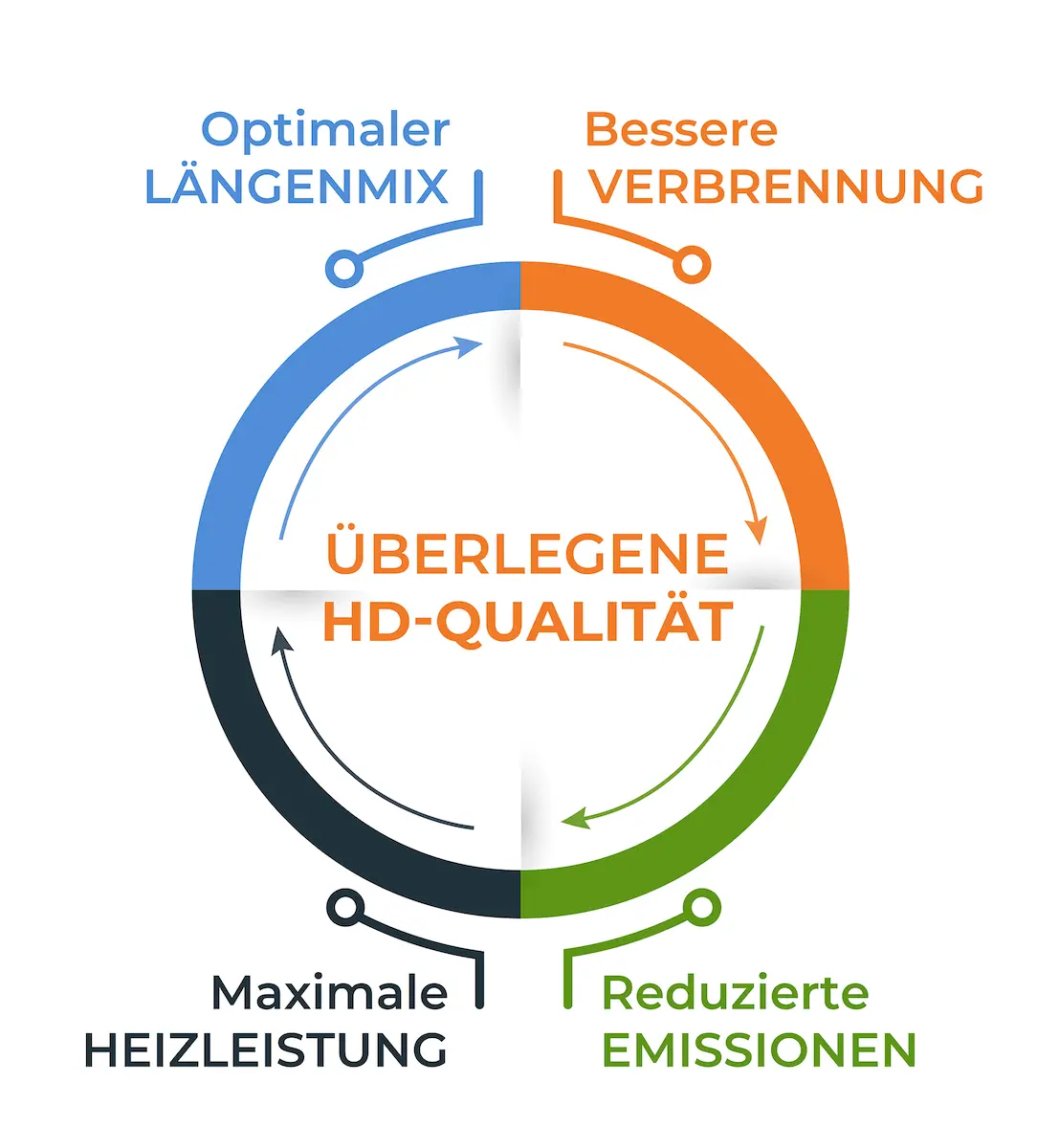

YOUR HEATING DOES BETTER WITH HD©

Conventional pellets require the heating system to constantly react to and readjust for disadvantageous volume fluctuations in the supply. HD pellets come with a particularly high ratio of perfect length range.This is the most important requirement for achieving the best possible fuel efficiency.

SAVE HEATING COST WITH HD©

Thanks to the homogeneity and the low proportion of short pellets, the combustion chamber is always evenly filled. This results in a firebed with a balanced pore distribution. The benefit of this: better ventilation between individual pellets. As HD quality wooden pellets burn more efficiently and cleanly, consumption is reduced.

REDUCE HARMFUL EMISSIONS WITH HD©

Due to expedient combustion the output of emissions is reduced likewise. Various research projects show that a large number of short wooden pellets has negative effects on the amount of emissions. Compared to conventional pellets HD pellets have an approx. 37% lower carbon monoxide (CO) proportion in the flue gas.

YOUR HEATING DOES BETTER WITH HD©

Conventional pellets require the heating system to constantly react to and readjust for disadvantageous volume fluctuations in the supply.

HD pellets come with a particularly high ratio of perfect length range.This is the most important requirement for achieving the best possible fuel efficiency.

SAVE HEATING COST WITH HD©

Thanks to the homogeneity and the low proportion of short pellets, the combustion chamber is always evenly filled. This results in a firebed with a balanced pore distribution. The benefit of this: better ventilation between individual pellets. As HD quality wooden pellets burn more efficiently and cleanly, consumption is reduced.

REDUCE HARMFUL EMISSIONS WITH HD©

Due to expedient combustion the output of emissions is reduced likewise. Various research projects show that a large number of short wooden pellets has negative effects on the amount of emissions. Compared to conventional pellets HD pellets have an approx. 37% lower carbon monoxide (CO) proportion in the flue gas.

FEWER FRAGMENTS AND LESS DUST

End surfaces of wooden pellets – owing to their brittle and porous form – are the main cause of abrasion and dust. Conventional pellets on average consist of around 2.2 million pellets per metric ton. This equals an added up end surface area of approximately 70 m2.

In comparison a metric ton of HD pellets – due to the high ratio of perfect length pellets – consists of only about 1.5 million individual pellets. That equals approx. 45 m2 of cumulative end surface area, a major advantage during filling as well as for storage and handling of pellets. Simply put: significantly fewer fine particles and less dust are produced.

SAVES ON HEATING COST

The perfect length distribution in HD pellets also allows for optimal filling of the combustion chamber. Thanks to the homogeneity and a low proportion of short pellets, the firebed has an even distribution of pores. The benefit: higher air permeability between individual pellets. Combustion is more efficient, consumption is reduced.

INCREASED HEATING EFFICIENCY

The greatest challenge for control systems regulating combustion of conventional wood pellets is inhomogeneity of the fuel. A heating system has to constantly react to detrimental fluctuations and readjust the configuration parameters. Thanks to the particularly high ratio of perfect length pellets, HD technology meets the main requirement for achieving highest levels of efficiency.

BETTER FOR THE ENVIRONMENT

Due to expedient combustion the output of emissions is reduced likewise. Various independent research projects show that a large number of short wooden pellets has negative effects on the amount of emissions. Compared to conventional pellets HD pellets have an approx. 37% lower carbon monoxide (CO) proportion in the flue gas* due to their homogenous size.

*Combustion and material handling assessment of wood pellets with improved physical properties, Technology and Support Centre in the Competence Centre for Renewable Resources, 03/2014

FEWER FRAGMENTS AND LESS DUST

End surfaces of wooden pellets – owing to their brittle and porous form – are the main cause of abrasion and dust. Conventional pellets on average consist of around 2.2 million pellets per metric ton. This equals an added up end surface area of approximately 70 m2.

In comparison a metric ton of HD pellets – due to the high ratio of perfect length pellets – consists of only about 1.5 million individual pellets. That equals approx. 45 m2 of cumulative end surface area, a major advantage during filling as well as for storage and handling of pellets. Simply put: significantly fewer fine particles and less dust are produced.

SAVES ON HEATING COST

The perfect length distribution in HD pellets also allows for optimal filling of the combustion chamber. Thanks to the homogeneity and a low proportion of short pellets, the firebed has an even distribution of pores. The benefit: higher air permeability between individual pellets. Combustion is more efficient, consumption is reduced.

INCREASED HEATING EFFICIENCY

The greatest challenge for control systems regulating combustion of conventional wood pellets is inhomogeneity of the fuel. A heating system has to constantly react to detrimental fluctuations and readjust the configuration parameters. Thanks to the particularly high ratio of perfect length pellets, HD technology meets the main requirement for achieving highest levels of efficiency.

BETTER FOR THE ENVIRONMENT

Due to expedient combustion the output of emissions is reduced likewise. Various independent research projects show that a large number of short wooden pellets has negative effects on the amount of emissions. Compared to conventional pellets HD pellets have an approx. 37% lower carbon monoxide (CO) proportion in the flue gas* due to their homogenous size.

*Combustion and material handling assessment of wood pellets with improved physical properties, Technology and Support Centre in the Competence Centre for Renewable Resources, 03/2014

Where can I buy HD pellets?

Simply enter your ZIP Code and start the search!

Where can I buy HD pellets?

Simply enter your ZIP Code and start the search!

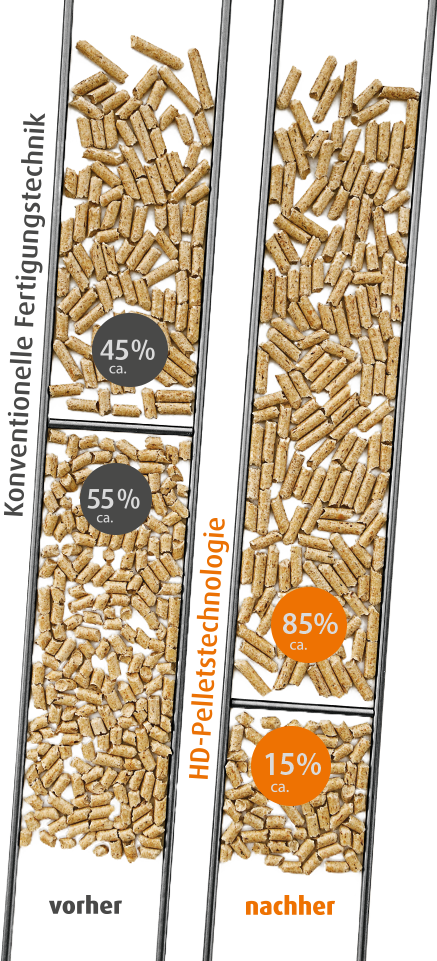

The HD technology is based on an entirely new manufacturing principle. Pellet strands are no longer “broken into pieces” but rather carefully cut to a defined length.

Subsequently, HD pellets are not only more even and have a higher average length; they also exhibit less damage on the surfaces and are more stable as a consequence. HD pellets therefore also offer best conditions for transportation and logistics. These unique qualities of HD pellets stay with them all the way into your storage!

HD pellets are available as bulk product and in 15 kg sacks – 66 sacks per pallet, 990 kg each. When buying HD quality pellets as bagged goods please take note of the HD quality label and certification number – it guarantees both quality and origin.

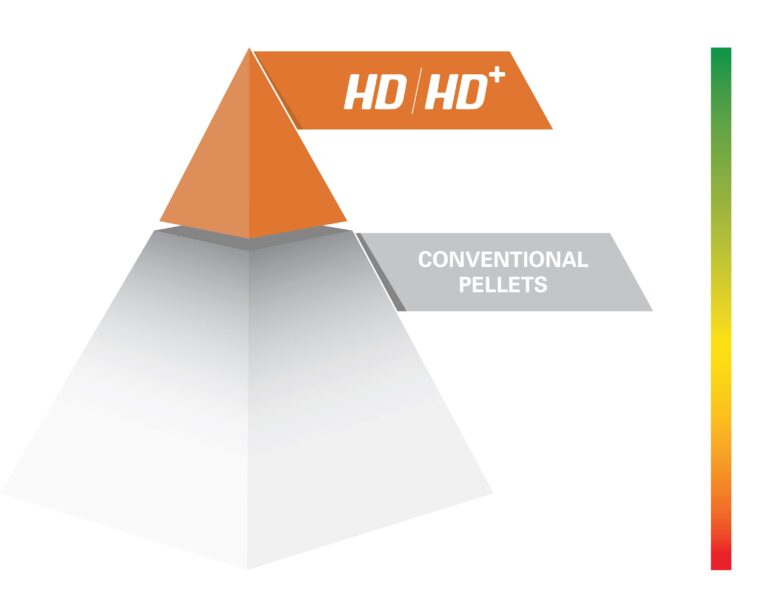

Minimum requirements for wood pellets in various areas of application, such as private individual furnaces, large plants, or industrial plants are defined by the European standard 14961-2.

Standards of certification systems such as ENplus or DINplus have been developed and implemented based on that. But within these standards, there is still a broad range of permissible qualities.

HD pellets significantly rise above.

The unique, patent-protected* HD technology combined with know-how and diligence of experienced pellet producers is a guarantee of our superior quality!

*including patent number DE 10 2013 022 395

Since its inception in 2014, we have continuously developed and improved the HD technology. Temporarily, two different system variants were in use at our manufacturers.

To differentiate between them, we had introduced the improved HD+ quality in addition to the HD quality. This was a big step forward and the development is still going on.

Today, all HD manufacturers have only one version of HD technology. The latest and best in each case.

HD quality now equals HD+ quality.

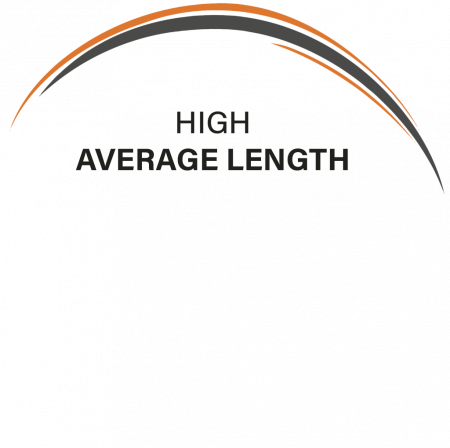

Maximum proportion in the ideal length range

small short portion

Maximum length can be precisely defined, overlengths are excluded

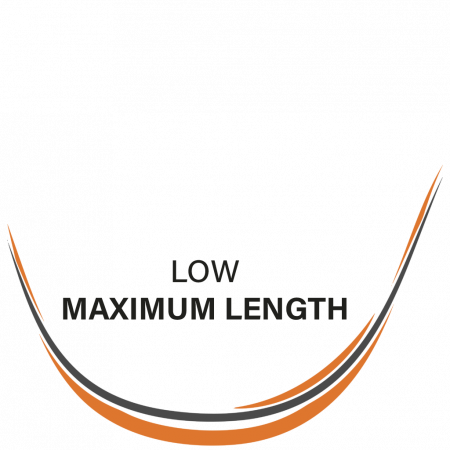

lower portion in the ideal length range

more breakage, dust and short pellets

Proportions in the long range are unavoidable, overlengths possible

You found your retailer is part of our HD network? Perfect!

Your usual retailer is not in our network yet? Talk to them about HD quality!

Conventional manufacturing technology only allows for a high average length if you accept a high proportion of very long pellets as the trade-off. Additionally, because of how the system operates, homogeneity is only possible with an extremely high proportion of short pellets. Since these two extremes are qualitatively insufficient, in practice you have to pick a more or less good compromise.

The patented HD technology by contrast is able – for the first time – to produce what cannot be achieved with conventional manufacturing technology: the absolute highest concentration of pellets within the optimal length range for combustion. And with a low proportion of short pellets but still not a single pellet longer than 30 mm. And with a low proportion of short pellets but still not a single pellet longer than 30 mm.

Receive our latest blog posts directly in your inbox!